Digital and artisan, the perfect match

When we think of craftsmanship, the first thing that comes to our minds is the hands, the people behind the work, the impossibility of exact repetition, the value of the unique.

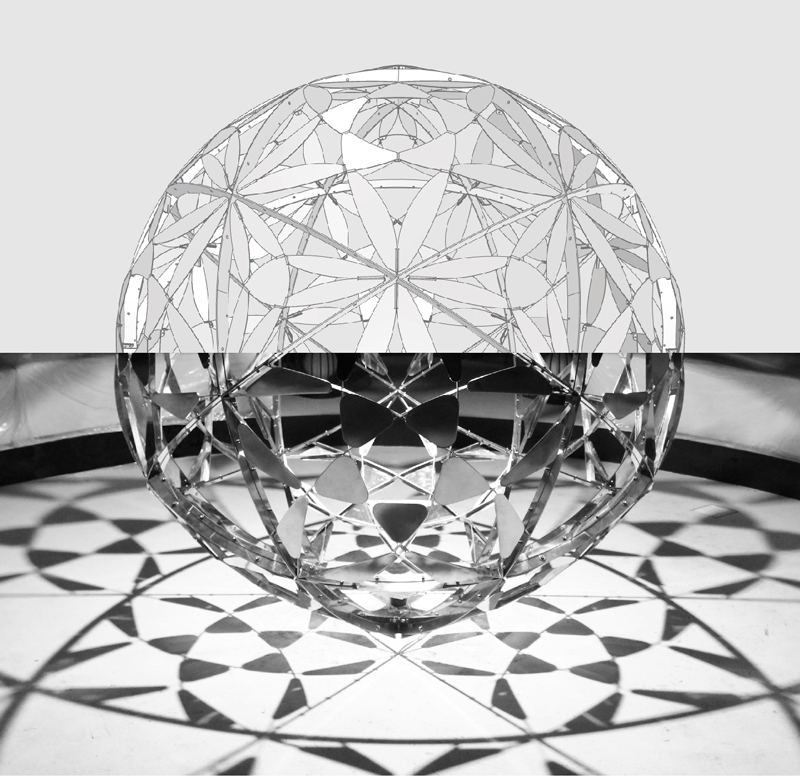

When we think of parametric design and digital fabrication, we think of machines, of perfect and fast execution, of impossible shapes.

They might seem opposite worlds but in fact, they have many points in common; they have much more to do with each other than either of them with classic industrial processes such as stamping, injection or extrusion.

Classic industrialization requires repetition. Each process requires a specific machine and each design requires a costly mould or specific tool. This means that the high cost of tooling and design fine-tuning has to be passed on to a very large number of parts.

Artisan and digital processes are much more flexible; in all of them, the only variable that increases the price is time. A craftsman can make 20 identical parts or 20 different parts in one day and the cost will be the same. A numerical control machine can make 20 of the same or 20 different parts in a day and the cost will be the same. Generally, it is not necessary to manufacture expensive tools or moulds only for a specific process. Hands and CNC machines are very versatile because in both cases there is intelligence, either human or artificial, behind the process.

At Atelier Mel, we have embraced this combination since the beginning of our career, and it is in this field that we have developed all our work.

It is a combination that allows us to tackle very complex projects, evaluate options in a very agile way and always materialize unique solutions. Without technology, we would need much more time and without manual processes, we would lose versatility and the intrinsic value of the artisan techniques.

Uniqueness comes together with exclusivity, with the ability to customize the design for the person who will own the artwork. With the combination of manual and digital, we fulfil this objective in an optimal way that allows us to be competitive.

Thanks to digital technology, we can determine the design variables and play with them during the design process. We can push the 3D model to the limit and virtually test all solutions to minimize the number of physical prototypes. During manufacturing, we can accurately handle numerous parts, and we can make sure that the assembly process is easy.

This combination is ideal for both handmade and digitally manufactured pieces. A unique handmade piece is perfectly complemented by digitally manufactured add-ons. These add-ons can be adapted, at no extra cost, to the irregularities of the handmade piece or to the unique configuration of standardized pieces. At the same time, a digitally manufactured parametric design will almost always require elements that are fabricated with other techniques and, in this case, making these parts manually is often the best option.

Above all, this combination of techniques makes us free. When repeating the same design is not a great advantage, the team is completely free to explore new paths that take us to a different place each time, to the right place for each of the projects.